Hydrogen

High-Performance Solutions for a Zero-Emission Future

The hydrogen energy landscape is expanding swiftly as global efforts to adopt zero-emission technologies intensify. Key players in this ecosystem, including hydrogen producers, alternative energy companies, infrastructure developers, and vehicle manufacturers, are actively scaling their operations to address the unique challenges of hydrogen containment and transfer. Essential to their success are fluid system components that are not only safe and reliable but also highly efficient.

Despite the critical need, finding suitable components can be difficult due to:

- The propensity of hydrogen gas, a small-molecule substance, to seep through even minimal gaps in connections, raising concerns over leaks and safety.

- The requirement for components that can withstand extraordinarily high pressures (up to 1050 bar [15,229 psi]), far beyond what traditional materials typically handle.

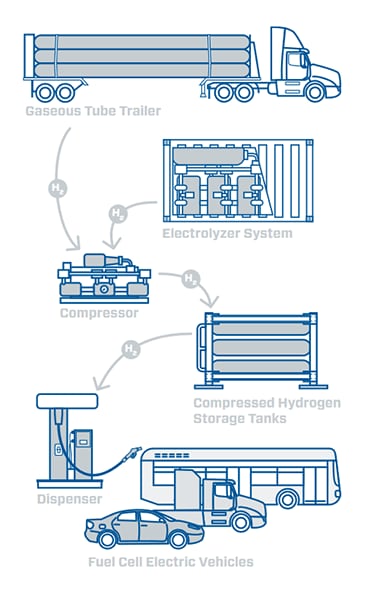

Hydrogen Applications

We are at the forefront of supporting the fast-paced growth of the hydrogen energy industry by providing vital fluid system solutions tailored for various stages including production, distribution, storage, and mobility. Our comprehensive offerings ensure efficiency and reliability throughout the following key areas of hydrogen applications:

- Electrolyzers

- Microgrids

- Fuel cells

- Virtual pipelines/tube trailers

- Refueling stations (infrastructure)

- ICE (Internal Combustion Engines)/FCEV systems

- Dispensers and priority panels

- Analyzer and sampling systems

Hydrogen Production

Unlocking the potential of hydrogen as an energy source begins with electrolysis, where water is split into hydrogen and oxygen using sustainably produced electricity. This critical step requires reliable, high-integrity fluid system components to manage the transfer of gases throughout the production process.

We offer comprehensive solutions for hydrogen electrolysis and fuel cell applications, providing expert knowledge and local support to maintain efficient operations.

We support hydrogen production with:

Hydrogen Infrastructure & Distribution Solutions

Efficiently delivering hydrogen from production to point-of-use requires a complex infrastructure of process, storage, and distribution systems designed to handle challenges of physical and virtual hydrogen transport.

Our systems support hydrogen storage and transportation at pressures up to 1050 bar (15,229 psi), maximizing energy density for effective delivery. We ensure that our pipelines are leak-proof, enhancing the profitability, reliability, and safety of hydrogen during transit. We emphasize straightforward installation and accessible local services to expedite the growth of hydrogen infrastructure and harness its full potential as an energy resource.

Swagelok supports hydrogen production with:

Hydrogen Refueling and Mobility

We are aware of the critical role that safe and reliable hydrogen refueling infrastructure plays as the market for hydrogen mobility continues to expand. To meet this growing demand, we ensure that every aspect of our system—from compressors and storage cylinders to priority panels, pressure control devices, and dispensers—is designed to the highest standards of quality and performance.

Safety is at the forefront of our hydrogen solutions, allowing every user to operate dispensers with ease and confidence. We engineer our components and connections to excel under the stress of rapidly changing temperatures and other demanding conditions encountered during dispensing cycles, ensuring robustness and durability.

As the infrastructure for hydrogen energy rapidly evolves, Nordival stays ahead by efficiently designing and assembling complex systems that are not only reliable but also scalable. Our commitment to innovation and excellence ensures that we meet the needs of today while preparing for the energy demands of the future.

Why Choosing the Right Materials is Crucial for Hydrogen Applications

Selecting the correct materials is critical in hydrogen mobility and transportation, as these systems face unique operational stresses. Our alloys, incorporating between two and ten elements, are precisely formulated to offer superior corrosion resistance.

Only select stainless steel grades, like Swagelok® 316, are designed to withstand the challenges of hydrogen systems, effectively preventing hydrogen embrittlement due to their superior strength and corrosion resistance properties. Opting for cheaper stainless steels with low chromium and nickel content could lead to increased corrosion and vulnerability to hydrogen damage. The choice of elastomeric components is also critical for maintaining long-term reliability and compatibility.

We're here to help you specify the appropriate materials for your projects, from fuel systems and tube trailers to hydrogen panels and dispensing units, simplifying the process with our expertise.

Hydrogen-Compatible Components

System Components

We provide an extensive array of fluid system components that meet the requirements for both EC-79 and HGV 3.1 across the H35 and H70 pressure classes, ensuring high-integrity solutions for any hydrogen-related application. Our offerings include:

- Assembly-by-torque (AbT) fittings

- FK series medium-pressure fittings

- VCO® O-ring face seal fittings

- VCR® metal gasket face seal fittings

- Pressure gauges

- All-metal hose

- Swagelok tubing

- Regulators

- Check Valves

These products are designed to support operations from hydrogen production to end-user delivery, handling pressures up to 20,000 psig. They are ideal for building infrastructure that manufactures, transports, compresses, stores, and fills hydrogen cylinders and for on-vehicle applications, aligning perfectly with Swagelok’s commitment to quality and safety in hydrogen mobility solutions.